Chapter 3.5

Safe access to large machinery systems

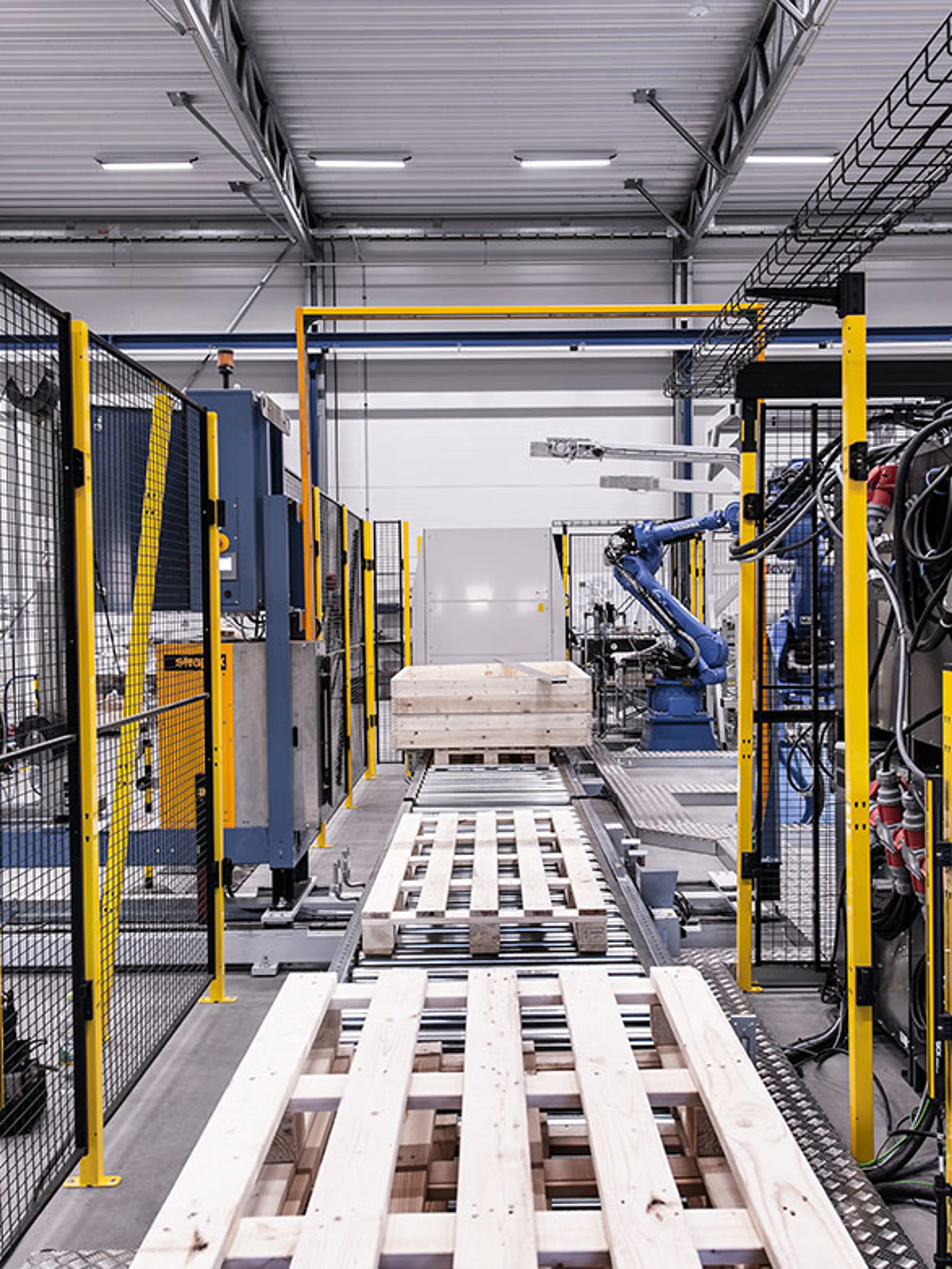

Today, large machinery systems are often enclosed by guard fencing. The integrated machinery behind the guard fence may include production machines, conveyors, robots, etc., and cover an entire factory hall or extend across several levels of a building. Automated warehouses likewise feature combinations of S/R machines, conveyors, and packaging systems. In this chapter, you will learn about the safety measures and standards necessary to ensure safe and efficient access to these complex systems.

Integrated manufacturing systems

These systems are often designed with task zones capable of operating independently, which promotes efficient workflows. Safety features, such as presence sensing devices and warning signals, ensure worker protection and adherence to the (EN) ISO 11161 standard.

Integrated manufacturing systems are programmed so that individual stations can perform tasks autonomously.

For example, a packaging machine might function independently from a robot feeding materials to it, while an output conveyor could operate separately or at intervals based on the packaging output.

When an issue arises in one task zone, it can often be resolved without halting the entire system or neighboring zones. This approach minimizes downtime and boosts production efficiency. Additionally, such independence allows for modular system upgrades, future-proofing operations by enabling seamless integration of advanced technologies. Similarly, retooling or even certain maintenance tasks can be completed without disrupting overall operations, maintaining a seamless workflow.

Individual safety features

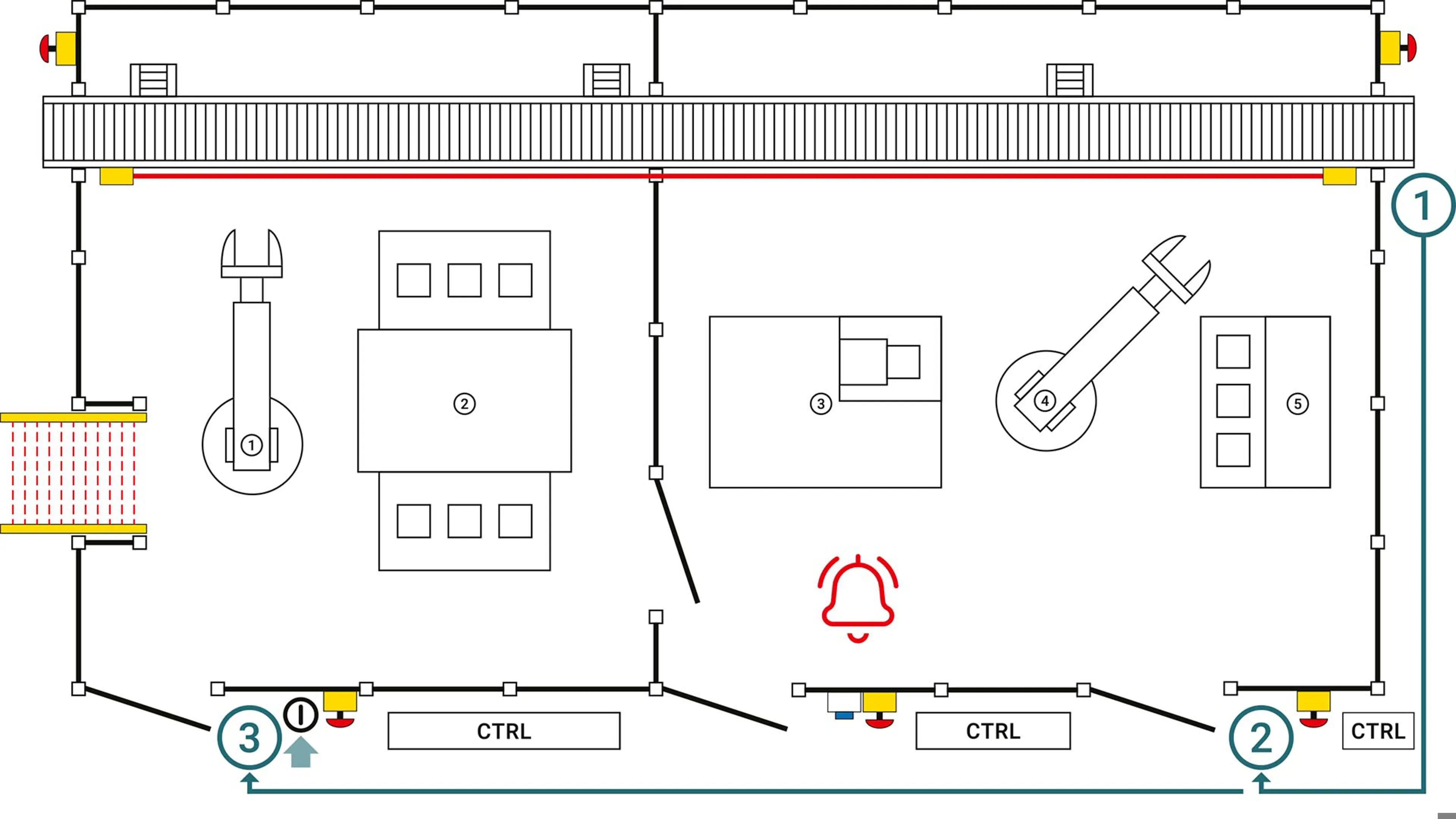

To be able to utilize versatile operating concepts, each task zone must have its own safety features allowing workers to enter a zone and work while the rest of the system continues running:

The following are examples of safety features that can be implemented:

- Presence sensing devices like light barriers, laser scanners, and contact mats inside the hazard zones to detect a worker and stop the hazardous operation.

- Reset and open individual doors while others remain locked.

- Switch-over to a set-up mode in one task zone while the others keep operating in automatic mode.

- Fences inside the fenced-in area which prevents a worker from migrating into a task zone that keeps running automatically.

This brings up numerous safety issues that need to be carefully considered. In 2008 ISO published a standard that contains many valuable rules for the safety of integrated manufacturing systems – (EN) ISO 11161.

One of the most difficult risks to deal with is that a system part may restart or accidentally be started while a person is still inside. To avoid that, several strategies have been developed to protect workers during such “whole body access.”

Visual or Audible Warning Devices

When a worker presses a start button outside the system, a warning light flashes or a horn sounds long enough for them to leave the hazard zone. At the end of the warning signal, the system starts.

Combined with:

- Start prevention buttons

- Rope switches

- Emergency stop buttons inside the safeguarded area

Additionally, install guard locking switches with escape release.

A factory floor plan illustration shows various machines and safety systems. The layout includes five numbered machines: two large wrench-shaped tools (1 and 4), a conveyor belt (2), a square machine (3), and a rectangular control box (5).